서브 페이지 내용

Product

Applications

• Misting and irrigation over benches

• Controlling humidity and temperature

• Minimum heightº : 1m

• Max. spacing between headsº : 0.9m

• Max. spacing between lateralº : 0.9m

• Max. distance of lateral from bench to edgeº : 0.1m

• Aeroponics cultivation angle 102˚@2bar

* noteº : It is applied for the seeding and propagation system.

• Controlling humidity and temperature

• Minimum heightº : 1m

• Max. spacing between headsº : 0.9m

• Max. spacing between lateralº : 0.9m

• Max. distance of lateral from bench to edgeº : 0.1m

• Aeroponics cultivation angle 102˚@2bar

* noteº : It is applied for the seeding and propagation system.

Features

• Three size intra-filtering structures such as 0.4, 0.6 and 1mm

• Perfect threaded union

• Having rooms for filtered debris in intra-structures

• Uniform coverage

• No dripping during operation

• Particle size : 71㎛(@2bar), 66㎛(@3bar)

• Fine mist without drifting of water droplets

• Perfect threaded union

• Having rooms for filtered debris in intra-structures

• Uniform coverage

• No dripping during operation

• Particle size : 71㎛(@2bar), 66㎛(@3bar)

• Fine mist without drifting of water droplets

White / Blue color nozzle

Applications

• Controlling humidity and temperature

• Providing good conditions for plant raising

• Providing good conditions for plant raising

Features

• Three size intra-filtering structures such as 0.4, 0.6 and 1mm

• Uniform coverage

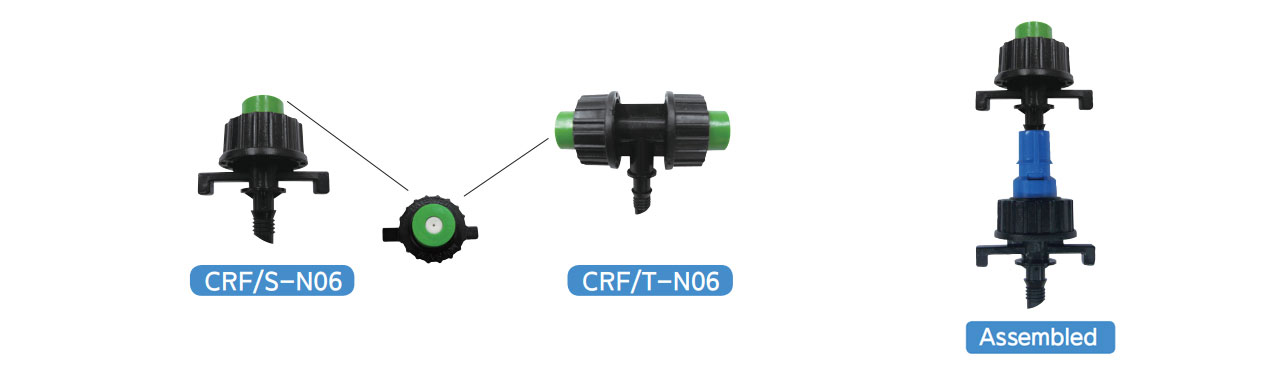

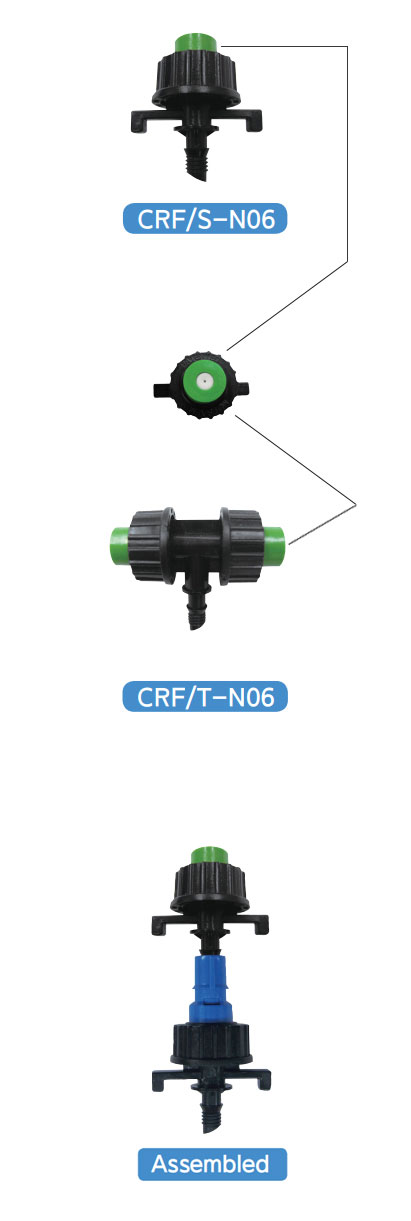

• Perfect threaded union(1 or 2 emitters) with anti-drainage(blue)

• PE and PVC connections

• Bayonet assembly(4 emitters) with anti-drainage(black)

• Fine droplet size

• Having rooms for filtered debris in intra-structures

• Anti-drainages are available

• Filtering requirements : 130 micron(120 mesh no.)

• Uniform coverage

• Perfect threaded union(1 or 2 emitters) with anti-drainage(blue)

• PE and PVC connections

• Bayonet assembly(4 emitters) with anti-drainage(black)

• Fine droplet size

• Having rooms for filtered debris in intra-structures

• Anti-drainages are available

• Filtering requirements : 130 micron(120 mesh no.)

Table 3. Fogger flow rate (ℓ/hr) according to the applied pressure

| Nozzle color | Green | Blue | White | |

|---|---|---|---|---|

| Pressure (bar) |

1 | 20 | - | - |

| 2 | 29 | 4.5 | 13.4 | |

| 3 | 33 | 5.4 | 16.0 | |

Table 4. Micro fogger technical data of MSF

| Model | Applied pressure @ 2bar | Applied pressure @ 3bar | ||

|---|---|---|---|---|

| Flow rate (ℓ/hr) | Average droplet size (㎛) | Flow rate (ℓ/hr) | Average droplet size (㎛) | |

| MSF/SP-20 | 29 | 72 | 33 | 66 |

| MSF/T-10 | 9 | 68 | 10.8 | 65 |

| MSF/F-20 | 18 | 21.6 | ||

| MSF/T-20 | 26.8 | 67 | 32.0 | 64 |

| MSF/F-40 | 53.6 | 56.0 | ||

Table 5. Micro fogger application and recommended spacing¹

| Model | For climate control (Cooling & humidifying) |

For pesticide spraying | For propagation² |

|---|---|---|---|

| MSF/T-10 | 1.5×3.0 m 2.0×4.0 m |

1.5×3.0 m - |

- |

| MSF/F-20 | 3.0×3.0 m 2.0×4.0 m |

- | 1.0×1.0 m |

| MSF/T-20 | 1.5×3.0 m 2.0×4.0 m |

1.5×3.0 m - |

- |

| MSF/F-40 | 3.0×3.0 m 2.0×4.0 m |

- | 1.0×1.0 m |

note 1 : Distance between heads × distance between laterals

note 2 : At 1.0m height above table/plants note 3 : Maximal operation pressure below 4 bar.

* It is recommendable that filtration mesh hole size should be approximately 10 times smaller than nozzle size in the watering resources for irrigation and in the fogger to control humidity and temperature.

note 2 : At 1.0m height above table/plants note 3 : Maximal operation pressure below 4 bar.

* It is recommendable that filtration mesh hole size should be approximately 10 times smaller than nozzle size in the watering resources for irrigation and in the fogger to control humidity and temperature.

Ceramic 포그

Applications

• Controlling humidity and temperature

• Spraying chemicals

• Spraying chemicals

Features

• Three size intra-filtering structures such as 0.4, 0.6 and 1mm

• Having rooms for debris in intra-structures

• Filtering requirements : 130 micron(120 mesh no.)

• Extra fine droplet size :54~58㎛@ 4~9bar

• Flow rate 9.8 ℓ/hr at 4~9bar

• Recommendable operation pressure ranges from 3 to 9bar

• Anti-drainages are available

• Having rooms for debris in intra-structures

• Filtering requirements : 130 micron(120 mesh no.)

• Extra fine droplet size :54~58㎛@ 4~9bar

• Flow rate 9.8 ℓ/hr at 4~9bar

• Recommendable operation pressure ranges from 3 to 9bar

• Anti-drainages are available

Vortex ultra micro foggers : using with pressurized water and compressed air

▶ Venturi type (Pat. US10,183,302 B2)

▶ Cap type (Pat. KR 10-1965427)

Application

1) Controlling temperature and humidity

2) Spraying chemicals

3) Phytosanitary

4) Vaccination

5) Reduction of odor

6) Dust suppression

7) Static electricity control

8) Foliar treatment

9) Disinfectant

2) Spraying chemicals

3) Phytosanitary

4) Vaccination

5) Reduction of odor

6) Dust suppression

7) Static electricity control

8) Foliar treatment

9) Disinfectant

Feature

1) The atomizing direction of Venturi type(IVF/S-xx, IVF/T-xx) can be easily changed

2) Low compressed air consumption and easy maintenance

3) Resistance to wear and abrasion

4) Easy to install air and water lines

5) No need of reverse osmosis system or decalcification water treatment

6) Good weatherability

7) Long atomizing spray distance is dependent on the air/water pressure ratio.

2) Low compressed air consumption and easy maintenance

3) Resistance to wear and abrasion

4) Easy to install air and water lines

5) No need of reverse osmosis system or decalcification water treatment

6) Good weatherability

7) Long atomizing spray distance is dependent on the air/water pressure ratio.

Table 6. Air flow rate and atomizing amount of water in the conditions of their applied pressure.

| Model | Applied pressure of Air/Water (bar) |

Atomizing amount (ℓ/hr) |

Consumption of air (ℓ/min) |

Sauter Mean Droplet Dia. (㎛) |

|---|---|---|---|---|

| IVF/x-N08 | 2 | 2.0 | 21 | 24 |

| 3 | 2.4 | 29 | 22 | |

| ICF/x-N09 | 2 | 1.5 | 15 | 23 |

| 3 | 1.7 | 20 | 22 | |

| ICF/x-N09 | 2 | 2.1 | 19 | 22 |

| 3 | 2.3 | 25 | 19 |

* Before it is applied, you 'd be better to have a test. Above data are for reference.

Ultra micro foggers : using with compressed air(External 2fluids foggers)

Application

1) Controlling humidity

2) Spraying chemicals in a small room

3) Reduction of odor as spraying chemicals

4) Dust suppression

5) Static electricity control

6) Disinfectant

2) Spraying chemicals in a small room

3) Reduction of odor as spraying chemicals

4) Dust suppression

5) Static electricity control

6) Disinfectant

Feature

1) Easy maintenance

2) Resistance to wear and abrasion

3) Easy to install air and water lines

4) No need of reverse osmosis system or decalcification water treatment

5) Good weatherability

6) Long atomizing spray distance

2) Resistance to wear and abrasion

3) Easy to install air and water lines

4) No need of reverse osmosis system or decalcification water treatment

5) Good weatherability

6) Long atomizing spray distance

Table 7. Air flow rate and atomizing amount of water in the conditions of their applied pressure.

| Model | Applied pressure of Air/Water (bar) |

Atomizing amount (ℓ/hr) |

Consumption of air (ℓ/min) |

Sauter Mean Droplet Dia. (㎛) |

|---|---|---|---|---|

| ECF/x-N09 | 2 | 2 | 40 | 19.3 |

| 3 | 2.2 | 43 | 16 | |

| ECF/x-N13 | 2 | 2.7 | 38 | 17.4 |

| 3 | 3 | 45 | 15.6 |

* Before it is applied, you 'd be better to have a test. Above data are for reference.